Fertilizer granulator

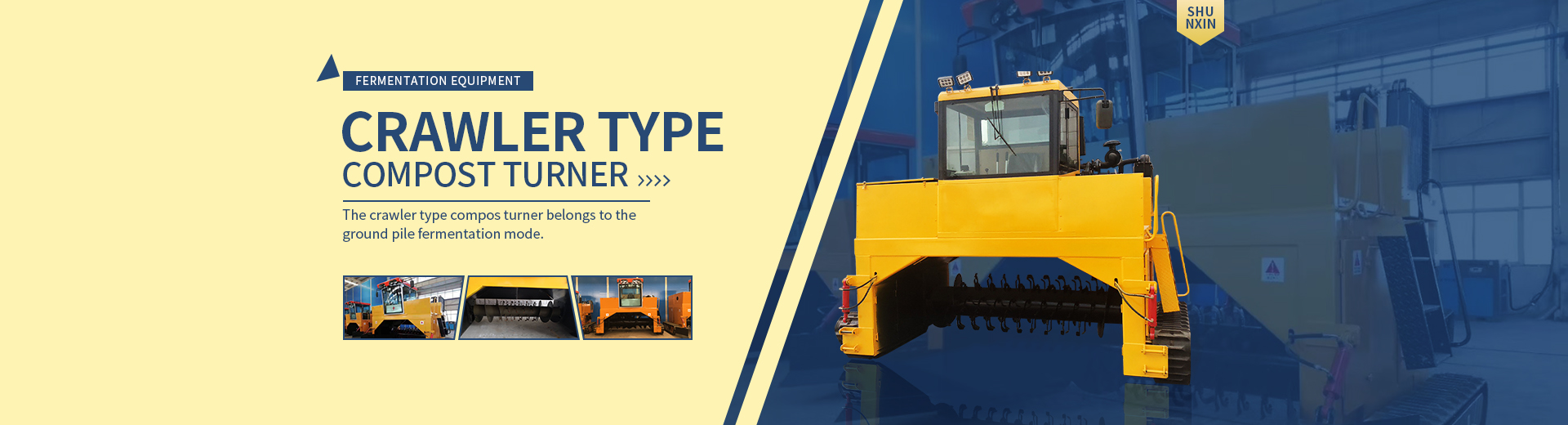

Compost equipment

Fertilizer equipment

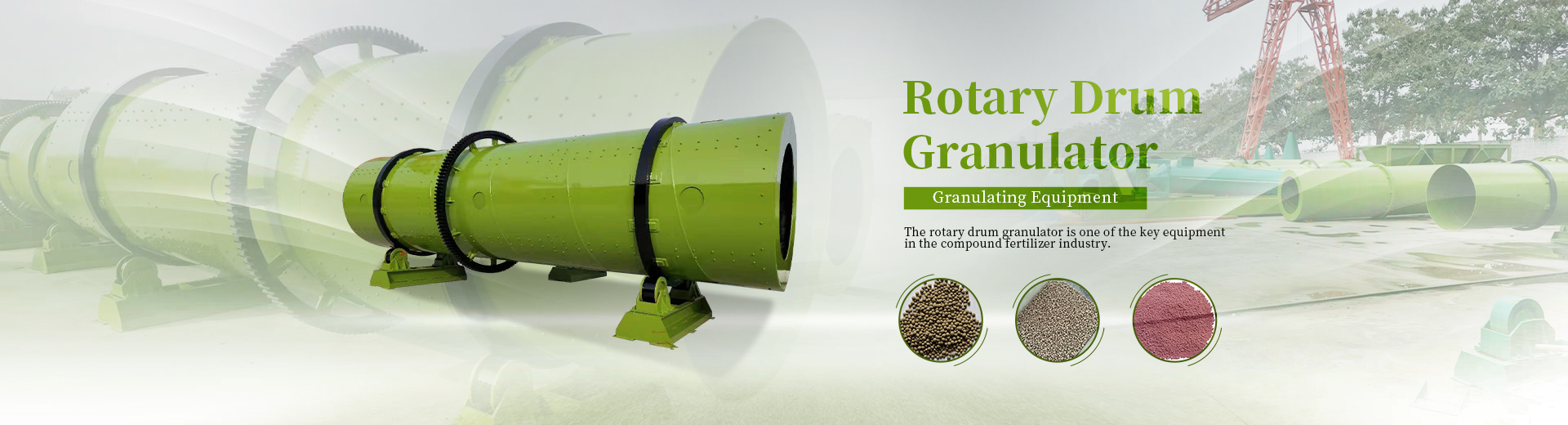

Fertilizer granulator

ABOUT US

Zhengzhou Shunxin Engineering Equipment Co., Ltd. is the leading brand of fertilizer equipment in China. The company is an environmentally-friendly high-tech enterprise specializing in the research and manufacture of organic fertilizer and compound fertilizer equipment. Our company was established on September 23, 2005. Our factory is located in Xingyang, Zhengzhou, with a standardized heavy industrial plant of 40,000 square meters. At the same time, it has introduced internationally advanced large and medium-sized metal processing equipment, including 10 machining centers, 3 laser cutting machines, and more than 80 types of equipment. We are China's self-operated import and export enterprise. Our company is Zhengzhou organic fertilizer equipment engineering research and development center, which provides a strong guarantee for the product quality and development of the enterprise.

Our company has a professional team composed of experts, professors and senior engineers. We are dedicated to the research, development, manufacture and promotion of organic fertilizer & compound fertilizer equipment. Our company was founded in 2005. After years of reform and development, Shunxin Machinery has won countless certificates of honor. These honors are Consumer approval of our products. We have gained a good credit and reputation in machinery industry.

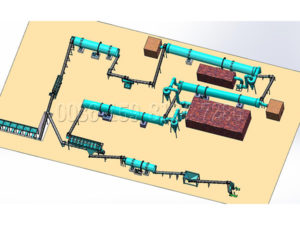

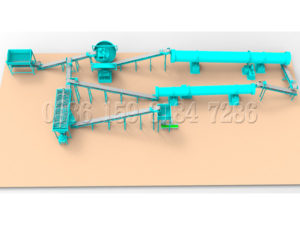

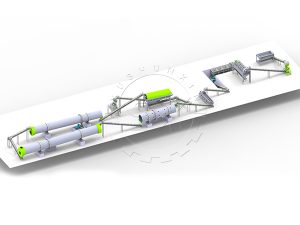

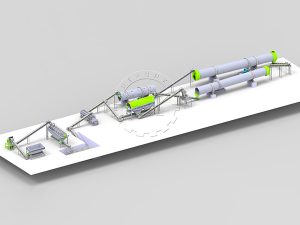

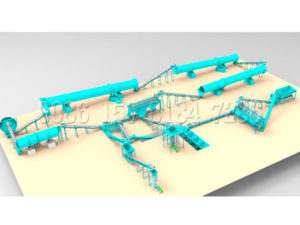

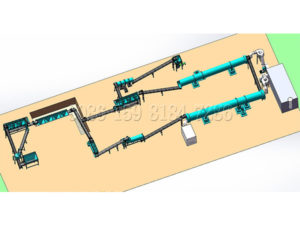

Our company's main business projects are the installation and production of fertilizer equipment, extrusion equipment, granulation equipment, drying equipment, mechanical equipment and accessories, and the design and construction of fertilizer engineering. Our equipment is complete in specifications and quality, and all indicators meet or exceed national standards. Our products are popular both at home and abroad. Our company have realized one-stop service for design, manufacture, installation, debugging, technical training.

NewsMore

-

Ecuadorian Customers Highly Praise the Wastewater Dewatering Machine

Recently, industrial customers from Ecuador have given high praise to the wastewater dewatering machine. This wastewater treatment equipment, with its efficient, stable performance and environmental advantages, has successfully helped customers solve ... Read more

-

Vietnam Customer’s High Praise for the Potassium Fertilizer Production Line

Recently, our potassium fertilizer production line was successfully put into operation in Vietnam and has received highly positive feedback from the customer. This production line, with its efficient production capacity and stable performance, has br ... Read more

-

Feedback of fertilizer solid-liquid separator from Mexico

Recently, a client from Mexico sent us a video saying, “The design of the machine is simple and easy to operate, and does not require complicated training. The dehydration efficiency is very high, the processing speed is fast, which greatly sav ... Read more

Shunxin BlogMore

How to store fertilizers?

Dry environment: Fertilizers should be stored in a dry place and avoid moisture. Moisture can cause fertilizers to clump, mold or decompose, affecting their fertilizer effectiveness. Good ventilation: The place where fertilizers are stored should be well ventilated to prevent gas accumulation, especially for organic fe ... + Read more

Which fertilizer is better, granular fertilizer or powdered fertilizer?

Granular Fertilizer: Slow-Release: Granular fertilizers are often slow-release, which means they gradually release nutrients over an extended period. This can provide a consistent supply of nutrients to plants over several weeks or months. Ease of Application: Granular fertilizers are typically easier to handle and spr ... + Read more

What equipment does the organic fertilizer factory have?

Composting Equipment: Compost Turners: Machines that mix and aerate compost piles, promoting decomposition and microbial activity. Windrow Turners: Used for large-scale composting, these machines turn and mix compost piles in long rows. Shredders and Crushers: These machines are used to break down and shred organic mat ... + Read more

What are the function of organic fertilizer?

Nutrient Supply: Organic fertilizers provide essential nutrients that plants need for healthy growth and development. These nutrients include primary macronutrients like nitrogen (N), phosphorus (P), and potassium (K), as well as secondary nutrients and micronutrients that are crucial for various plant processes. Slow ... + Read more

How to make organic fertilizer for business?

Research and Planning Conduct market research to understand the demand and potential competitors in your area. Identify the types of organic fertilizers you want to produce (compost, vermicompost, etc.). Determine your target audience (e.g., home gardeners, farmers, etc.). Create a business plan outlining your objectiv ... + Read more

How to decompose cow dung quickly?

Composting: Composting is an effective way to decompose cow dung rapidly. Create a compost pile in a well-ventilated area. Mix the cow dung with other organic materials like straw, leaves, or vegetable scraps. Turn the pile regularly to aerate it and maintain moisture levels. The composting process generates heat, whic ... + Read more

How to produce powder organic fertilizer?

Choose Organic Materials: Select a combination of organic materials that are rich in nutrients. Common organic materials used in organic fertilizer production include compost, manure (such as cow, chicken, or horse manure), bone meal, fish meal, seaweed, and plant residues. These materials provide essential nutrients l ... + Read more

What can you do with horse manure?

Horse manure, like other forms of animal waste, can be used in various ways. Here are a few common uses for horse manure: Fertilizer: Horse manure is a valuable source of organic matter and nutrients, including nitrogen, phosphorus, and potassium. It can be composted and used as a natural fertilizer to improve soil qua ... + Read more

-Fertilizer-Production-Line-300x225.jpg)