Rotary Drum Fertilizer Screening Machine

- Product details

The rotary drum fertilizer screening machine is a new type self-cleaning dedicated device for screening materials on the basis of electric vibrating screen and normal mesh rotary screen. It is widely used in screening various solid materials whose particle size is less than 300 mm. It features high screening efficiency, low noise, small dust emission, long service life, convenient maintenance, etc. Its screening capacity is between 1 t/h to 20t/h.

- Performance characteristics

- High screening efficiency. Due to its plate-type cleaning mechanism, the screen cloth will never be clogged, improving the screening efficiency of the equipment.

- Good working environment. The whole screening mechanism are designed in the sealed dust cover, completely avoiding dust flying in the screening process.

- Low equipment noise. The noise produced by materials and rotating screen is completely isolated by sealed dust cover, reducing the equipment noise.

- Long service life. The screen cloth are composed of several round flat steel, whose section area is much larger than those of other separating device.

- Convenient maintenance. There are watch windows on both sides of the sealed dust cover, and the equipment operation condition can be observed by our staff at any time.

- Working principle

The working principle of a self-cleaning cage type rotary drum screening machine is as following: the center separating bowl is driven to rotate reasonably by gearbox decelerating system. The center separating bowl is composed of several sieves of round flat steel rim. The center separating bowl is installed at a sloping sate with the ground. First, the materials are adding into drum screen from the upper end of the center separating bowl, then the fine materials are separated by the sieve space from top to bottom, finally the rough materials come out from lower end of the separating bowl through the rotating of the separating bowl. This machine is equipped with plate-type self cleaning screening mechanism. In the process of screening, the screening mechanism works continuously on the screening body through relative movement of the screening mechanism and the screening body, thus making screen body keep clean during working time. So it keep high screening efficiency without screen binding.

Working Video

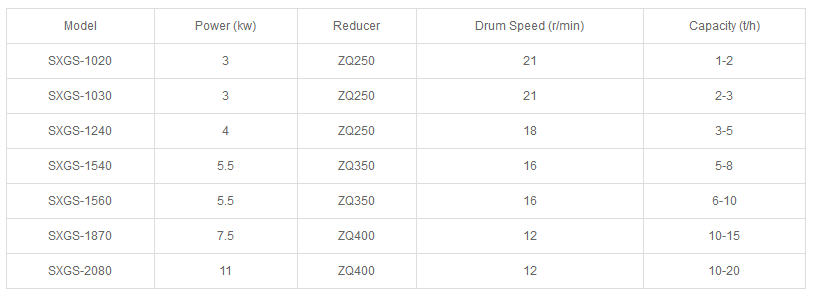

Technical Parameters